by Lauren Longo | Jul 25, 2024 | Uncategorized, Critical Lift, Double Girder Cranes, Industry News

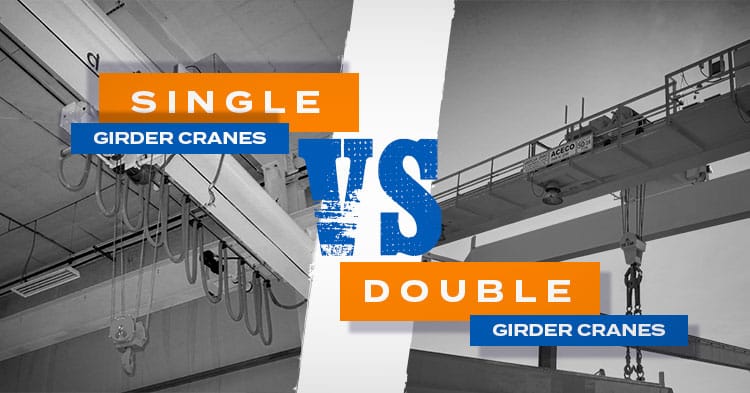

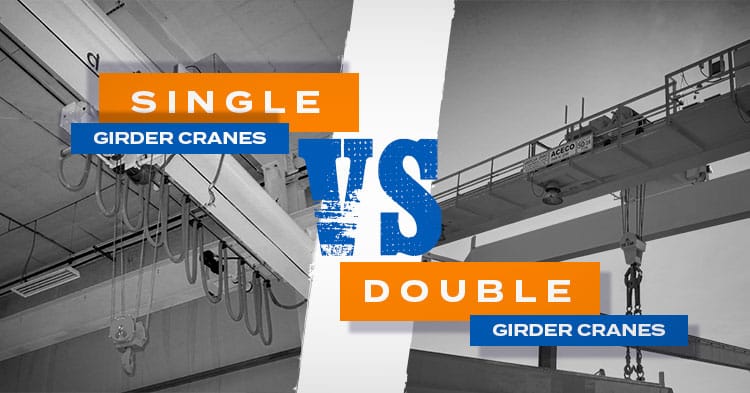

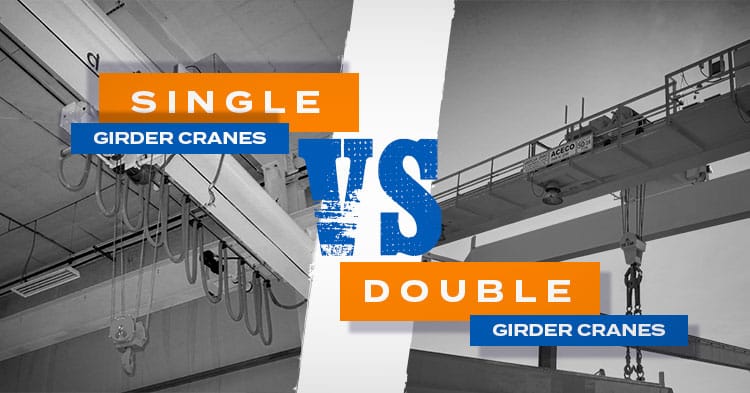

When it comes to selecting the right crane for your operations, understanding the differences between single and double girder cranes is essential. At American Crane & Equipment Corporation, we offer a variety of crane solutions tailored to meet your specific...

by Lauren Longo | Jul 9, 2024 | Critical Lift, Double Girder Cranes, Featured Products, Manufacturers, News and Events Post, Outdoor Crane Applications, Overhead Equipment

At American Crane & Equipment Corporation (ACECO), we believe that understanding the intricacies of crane types and their components is essential for efficient and safe operations. Cranes are indispensable in construction, manufacturing and logistics, enabling the...

by American Crane and Equipment Corporation | Aug 14, 2018 | Aerospace, Double Girder Cranes

Aerospace manufacturers regularly lift, turn, and position large components when assembling their products. These lifts are deemed critical since the items being hoisted are usually cumbersome, sensitive to damage, and extremely expensive. The margin for error in...