Transforming Metals into Workable Forms

Ingot Handling: Shaping Metals for Industry

Metals, without exception, are cast into ingots for the sole purpose of storage, transportation, or further processing. Steel, gold, and silver are the most frequently cast into ingots for such purposes.

To create ingots, raw materials of exceptionally high purity must be melted to liquid and immediately poured into molds to solidify into hardened, valuable forms. It’s crucial to note that ingots can vary significantly in size and weight, ranging from just a few pounds to hundreds of tons or more, depending on the material and desired use. It’s worth mentioning that common ingot forms include sheets, bars, and plates.

From Raw Ingots to Industrial Essentials

Understanding the Diverse Applications of Ingots

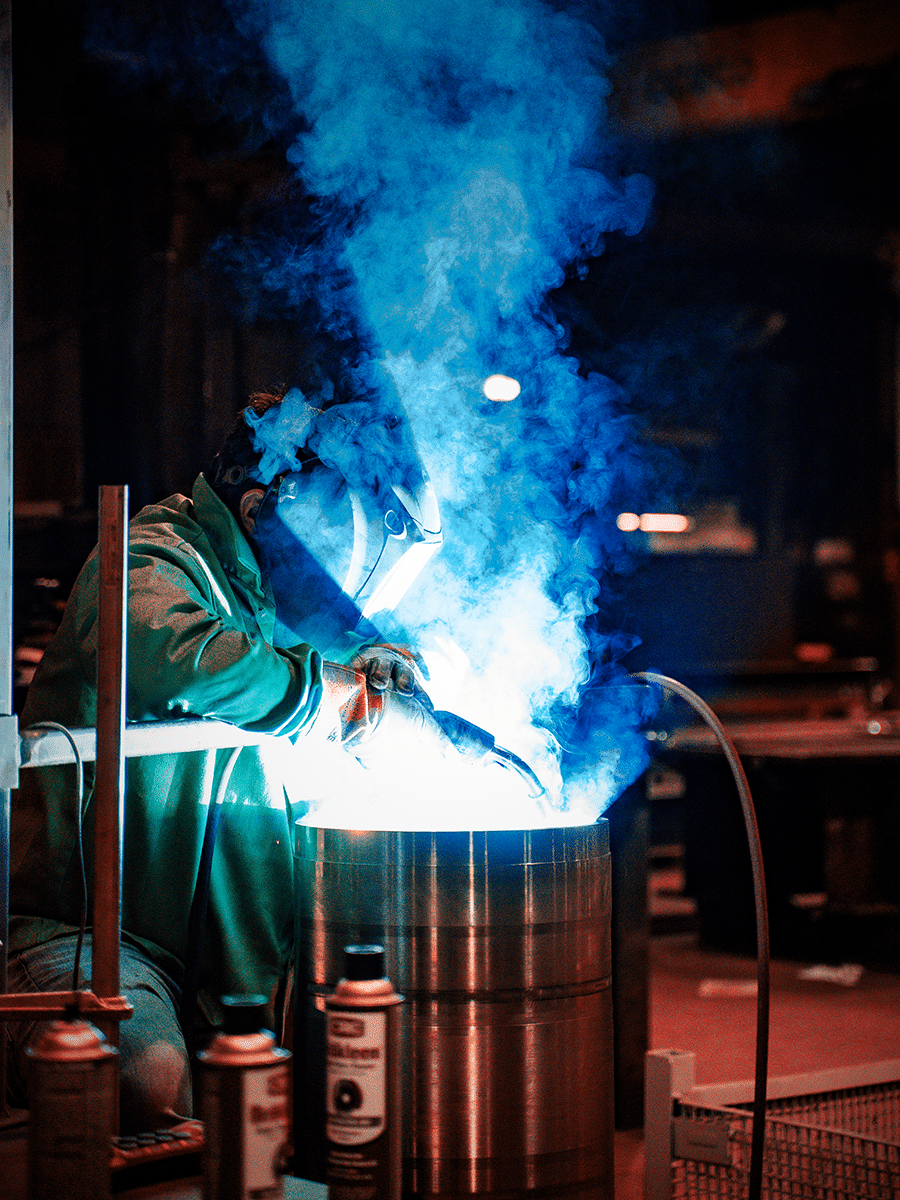

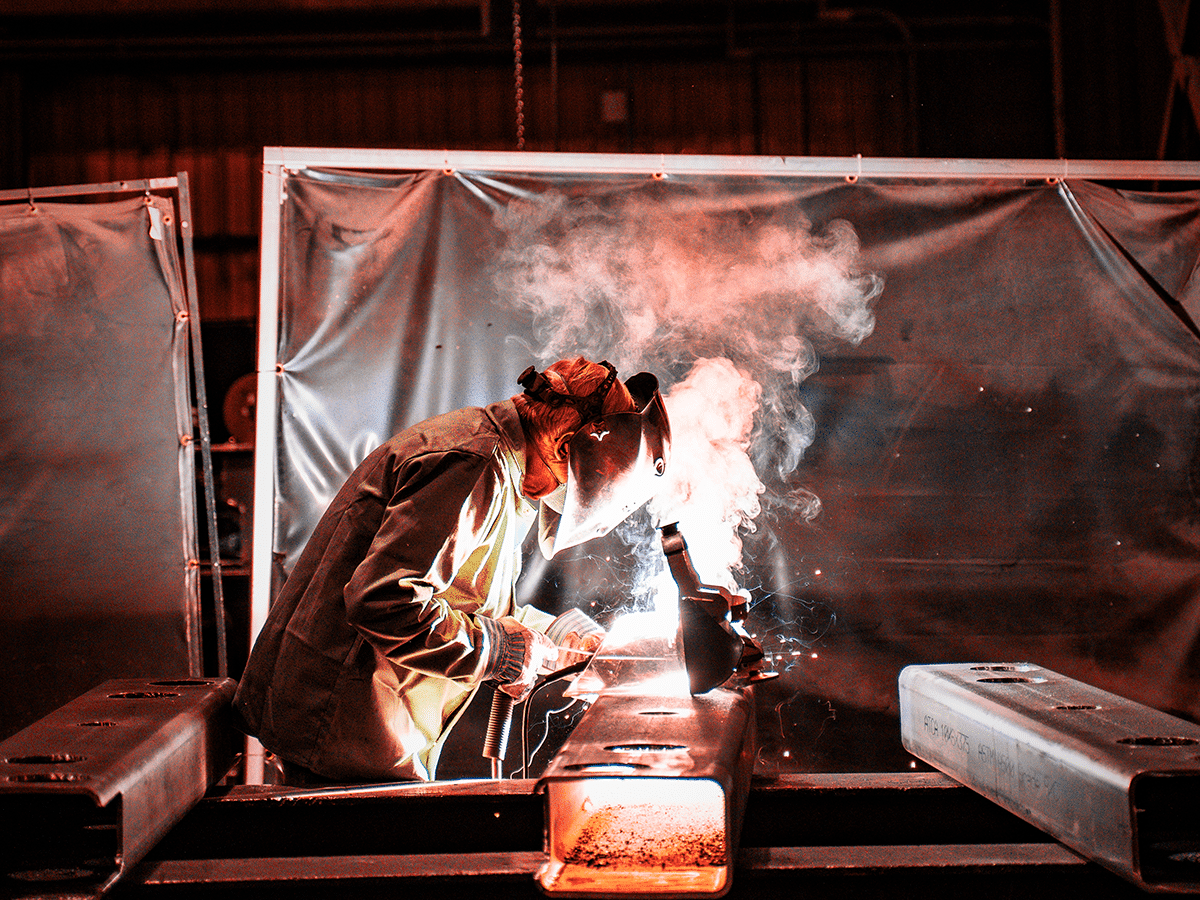

In various manufacturing processes, ingots often undergo secondary shaping procedures before they can be utilized. These processes may involve cutting, milling, or hot or cold working to prepare the ingots for use in machining or other fabrication procedures.

Gold bars are undoubtedly one of the most well-known and widely used forms of ingots. In fact, they are commonly used as currency throughout the world. It is important to note that ingots have extensive and diverse applications, with numerous examples including:

- Serving as raw material for creating alloys

- Production of cast, grain-free turbine blades

- Minting coins

- Fabrication of large steel structural components, such as I-Beams

- Manufacturing rails for railroads

Without a doubt, ingots are invaluable and indispensable in a multitude of industries and manufacturing sectors. They have become integral to various manufacturing processes, and their significance cannot be overstated. These solid metal blocks are essential in producing countless products, contributing significantly to their quality, strength, and consistency.

Elevating Ingot Handling Efficiency

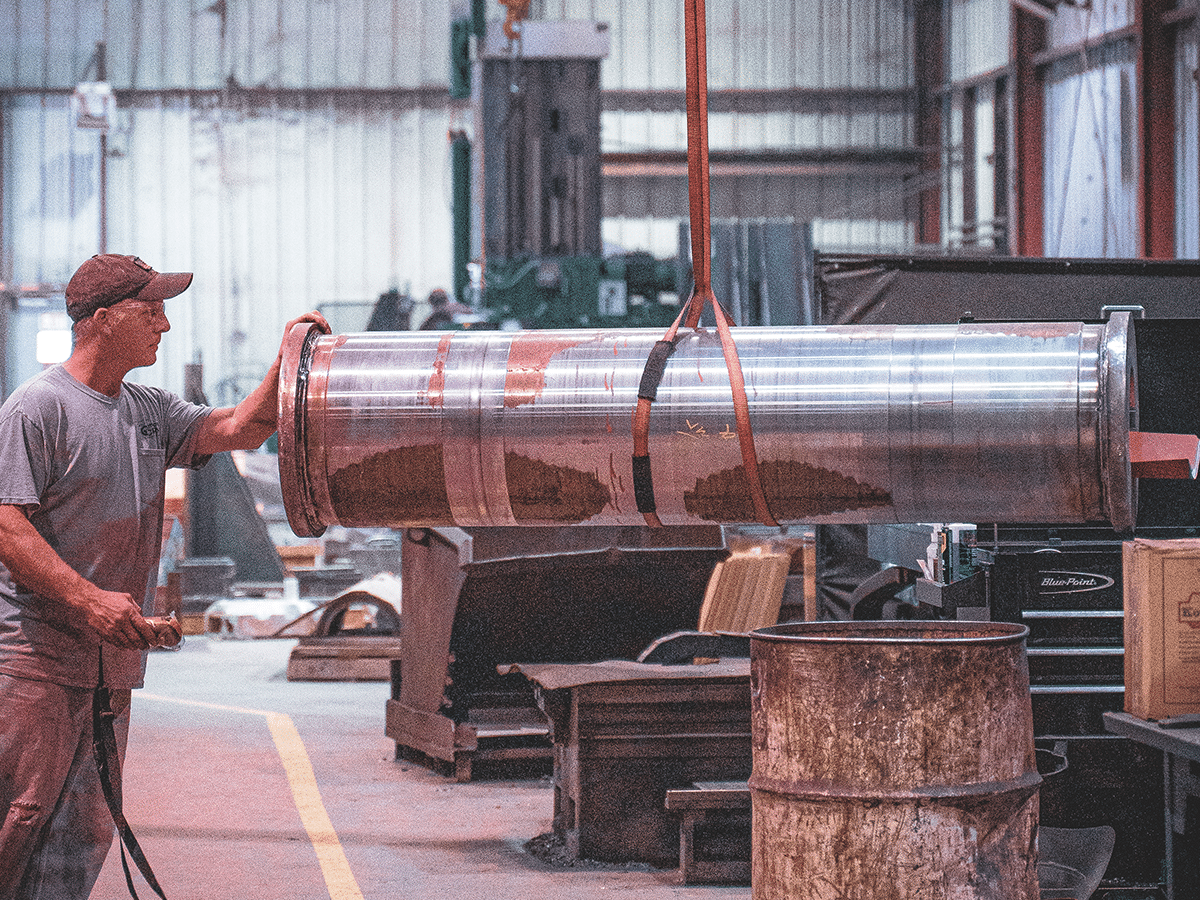

Custom Ingot Handling Solutions by ACECO

Ingots come in various sizes, some small enough to stack on pallets weighing hundreds or thousands of pounds. In contrast, others can consider hundreds of tons and are used to construct significant components. But don’t worry about their lifting challenges – American Crane and Equipment has covered you with our custom-designed lifting solutions that can handle nuggets of any size or configuration. Our equipment is built tough to withstand even the harshest industrial environments, from forges to factories, and is designed with quality, reliability, and operator safety in mind. We also maintain a substantial inventory of replacement parts, and our service technicians are available 24/7 to respond to emergencies and minimize operational downtime.