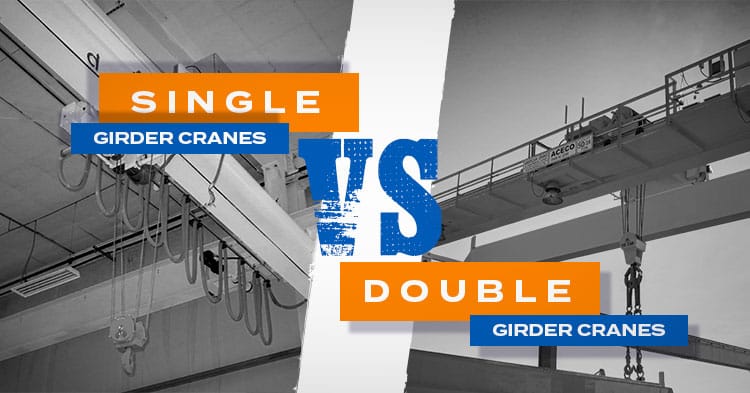

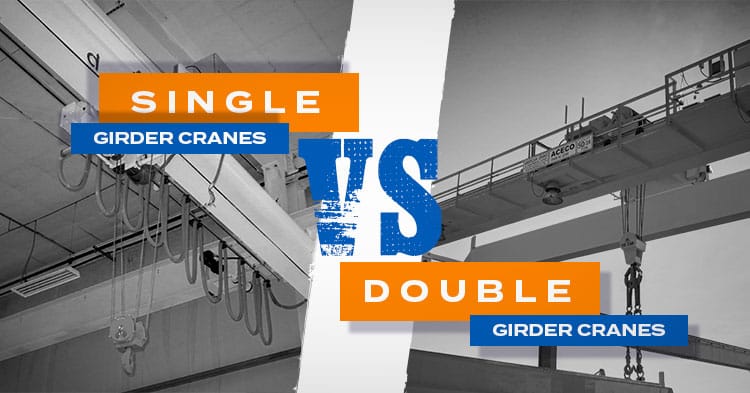

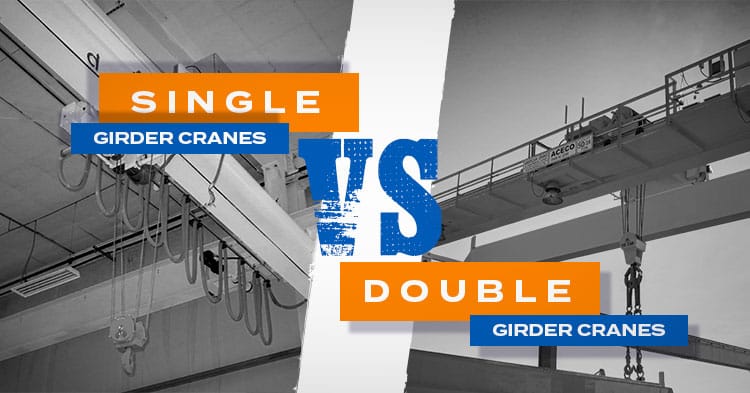

by Lauren Longo | Jul 25, 2024 | Uncategorized, Critical Lift, Double Girder Cranes, Industry News

When it comes to selecting the right crane for your operations, understanding the differences between single and double girder cranes is essential. At American Crane & Equipment Corporation, we offer a variety of crane solutions tailored to meet your specific...

by Lauren Longo | Jul 16, 2024 | Uncategorized

Overhead cranes and hoists play an integral role in almost every industry, facilitating the efficient and safe movement of heavy materials. Selecting the appropriate crane for your application is crucial for operational safety, maintenance and overall efficiency....

by Lauren Longo | Jul 4, 2024 | Critical Lift, Industry News, Manufacturers, Outdoor Crane Applications, Overhead Equipment

Safety is a main concern on any job site. At American Crane & Equipment Corporation, we understand the importance of maintaining the highest safety standards to protect your team and equipment. According to the Occupational Health and Safety Administration (OSHA),...

by Lauren Longo | Jul 2, 2024 | Critical Lift, Industry News, Manufacturers, News and Events Post, Overhead Equipment

Selecting the right crane for your needs can be a complex and time-consuming task. With a variety of cranes and hoists available on the market, understanding the key factors that influence your decision is crucial. Here are six essential considerations to help you...

by Michele Kienle | Nov 8, 2023 | Manufacturers

For over 50 years American Crane & Equipment Corporation (ACECO) has been steadfastly dedicated to delivering excellence in both our products and customer service. We aim to be your trusted partner, providing you with the essential components you need precisely...