American Crane’s Comprehensive Parts and New Equipment Solutions

Leave a CommentAt American Crane and Equipment Corporation (ACECO), we understand that minimizing downtime is essential for maintaining productivity and keeping projects on track. That’s why we offer a wide range of high-quality parts and new equipment solutions through our online store. Whether you’re replacing a single part or upgrading your entire system, our extensive inventory ensures you’ll find exactly what you need to keep your machinery running efficiently.

Parts for Every Need

Our online store features a vast selection of parts from major manufacturers, designed to meet the specific needs of various industries. From push button pendants to motor components, we stock everything you need to keep your equipment in top condition. Some of the most popular parts we carry include:

- Chain & Wire Ropes

- Brake & Motor Components

- Electrical Components

- Trolley Parts

- Festoon Systems

- Conductor Bar Systems

We make it easy to browse by part or vendor, allowing you to find the exact replacement components quickly. Our multi-line search functionality ensures you can search for thousands of parts by part number or explore categories like control components, brake assemblies, and gearing parts.

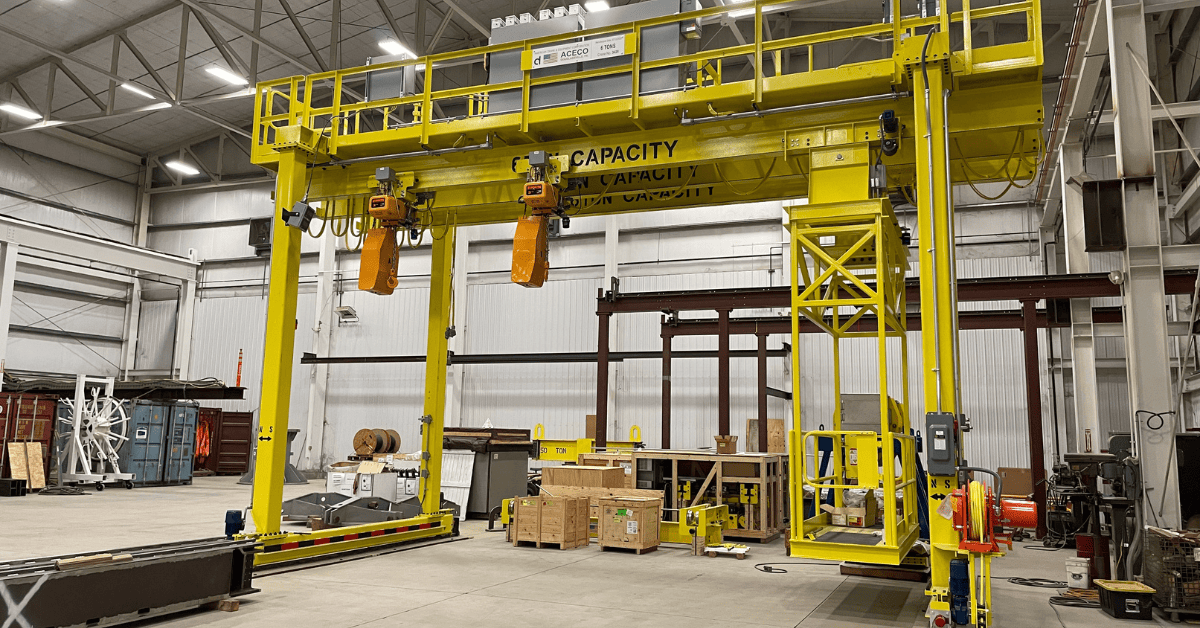

Expanding Our Selection with New Equipment

In addition to replacement parts, we regularly update our store with new equipment from industry leaders like Columbus McKinnon (CM), Yale, Coffing, and Gorbel. These products are designed to enhance industrial performance, whether you need electric chain hoists, jib cranes, or radio remote controls. We continually expand our offerings to ensure you have access to the latest innovations in material handling and lifting solutions.

Popular new equipment categories include:

- Electric and Manual Chain Hoists

- Jib and Gantry Cranes

- Workstation Cranes

- Powered Hoists and Trolleys

By offering products from trusted brands like Magnetek, Cleveland Tramrail, and Duct-O-Wire, we ensure you receive reliable, durable equipment tailored to your specific application needs.

Why Choose American Crane?

When you choose American Crane, you’re not just purchasing parts or equipment–you’re gaining a trusted partner. Our team is committed to providing exceptional service, offering continuous site support and expert guidance throughout the lifecycle of your product. From installation to ongoing maintenance, we’re here to help.

Ready to optimize your operations with high-quality parts and equipment? Visit our online store, request a quote, or contact us today for more information!

In the fast-paced world of automotive manufacturing, efficiency and precision are paramount.

In the fast-paced world of automotive manufacturing, efficiency and precision are paramount.