Crane 101: Types of Cranes, Basic Terms and Structures

2 Comments

At American Crane & Equipment Corporation (ACECO), we believe that understanding the intricacies of crane types and their components is essential for efficient and safe operations. Cranes are indispensable in construction, manufacturing and logistics, enabling the lifting and moving of heavy loads with precision. This guide provides an overview of crane types, basic terminology and key structures involved.

Types of Cranes

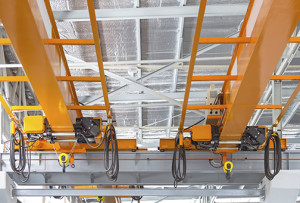

- Overhead Crane: Features a movable bridge carrying a hoisting mechanism that travels on an overhead fixed runway structure.

- Gantry Crane: Similar to overhead cranes, but with the bridge supported on two or more legs running on fixed rails or runways.

- Jib Crane: Has a bridge girder (boom) fixed at one end, often hinged to allow rotation, providing flexibility in small spaces.

- Single Girder Crane: Runs on a single bridge girder, suitable for lighter loads.

- Double Girder Crane: Utilizes two bridge girders, ideal for heavier loads and longer spans.

Learn more: The Basics of Cranes and Hoists

Basic Terms

Crane Components

- Bridge: The main horizontal structure that supports the trolley and travels parallel to the runway.

- Trolley: Carries the hoisting mechanism and moves along the bridge.

- Hoist: The mechanism used for lifting and lowering loads.

- End Trucks: Support the bridge girders and house the wheels that travel on the runway rails.

Learn more: The Four Key Crane Components

Structural Elements

- Bridge Girder: The primary horizontal beam of the crane bridge.

- Box Section: A rectangular cross-section of girders, enhancing strength and stability.

- Camber: An upward curve in the girder to counteract deflection.

- End Tie: Connects the ends of the girders to maintain structural integrity.

Load and Capacity

- Capacity: The maximum load a crane is designed to handle, measured in tons.

- Rated Load: The safe maximum load a crane can handle.

- Critical Load: Any load whose uncontrolled movement could compromise safety systems.

Crane Movement

- Reeving: The path the hoist rope takes around various pulleys and sheaves.

- Span: The horizontal distance between runway rails.

- Hook Approach: The minimum horizontal distance between the runway rail and the hook.

Safety Features

- Anti-Collision: Prevents cranes from contacting each other.

- Single Failure Proof: Design features ensuring that a single component failure won’t result in load loss.

- Holding Brake: Automatically prevents motion when power is off.

- Regenerative Braking: Uses electrical energy to control speed and feed it back into the power system.

Glossary of Terms

- Adjustable Frequency Drive: Motor controller converting fixed frequency AC power for speed control.

- Auxiliary Hoist: A secondary hoist for lighter loads at higher speeds.

- Bogie: Short end truck distributing crane wheel loads.

- Clearance: Minimum distance from crane extremity to nearest obstruction.

- Collectors: Devices collecting current from conductors for the bridge and trolley.

- Festooning: Power supply method for a traveling hoist.

- Sheave: A grooved wheel or pulley guiding the hoist rope.

- Top Running Crane: End trucks supported on rails atop runway beams.

- Under Running Crane: Movable bridge running on the lower flanges of a fixed runway structure.

- Wheel Load: The load on any wheel without vertical inertia force.

Understanding these terms and structures is crucial for anyone involved in crane operation, maintenance, or purchasing. At ACECO, we are committed to providing high-quality cranes and equipment, and we believe that informed customers are empowered customers. Proper knowledge ensures the safe and efficient use of cranes, contributing to overall project success. To learn more, visit our Glossary Guide for Cranes.

Cranes utilize hooks, hoists, magnets, and other devices to transport loads. A crane’s operational range depends on the axes and rotational capabilities.

Cranes utilize hooks, hoists, magnets, and other devices to transport loads. A crane’s operational range depends on the axes and rotational capabilities.