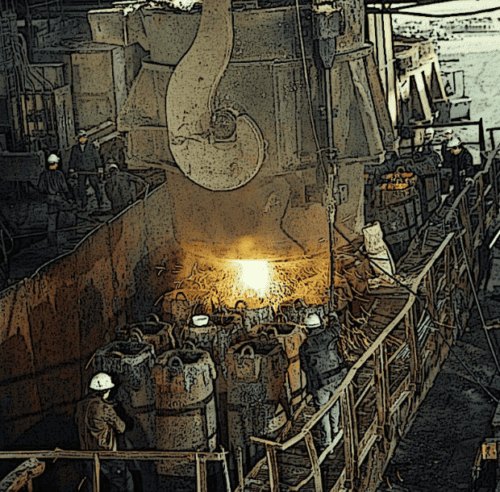

Ingot Handling

Raw materials—usually metals—are often cast into ingots so that they can be processed further. Ingots also facilitate easier storage or transportation of raw materials. Steel, silver, and gold are all commonly cast into ingots for transport or manufacturing.

To create ingots, raw material of high purity is melted into a liquid state, then poured into a mold and chilled to into a hardened, useful form. Ingots may vary widely in size, weighing anywhere from several pounds up to hundreds of tons or more depending on the material and intended purpose. Common forms for ingots include sheets, bars, and plates.

Applications for Ingots

Before they can be used for manufacturing, ingots often require a secondary shaping process. They may be cut, milled, or undergo hot/cold working processes in preparation for use in machining or other fabrication processes.

The gold bars used as currency are perhaps one of the most commonly known forms of ingots. The applications for ingots are endless, but common examples include:

- Raw material for making alloys

- Creating cast, grain-free turbine blades

- Minting coins

- Preparing

- Fabricating large steel structural components, such as I-beams

- Rails for railroads

Ingot Handling Equipment from American Crane and Equipment

Smaller ingots are often stacked and stored on pallets that weigh hundreds or thousands of pounds, depending on the material. Larger ingots, such as those used in producing construction components, can weigh hundreds of tons on their own. Moving these items can present unique lifting challenges.

American Crane and Equipment can custom design and manufacture lifting solutions of any size and shape to lift ingots of all sizes and configurations. Our custom built equipment can withstand the harshest industrial environments, ranging from forges to factories. Our equipment is built with quality, reliability, and operator safety in mind.

We maintain a substantial inventory of replacement parts and our service technicians are available 24/7 to respond to emergencies and minimize operational downtime.

For more information about ingot handling equipment or our other lifting solutions, please contact us or request a quote.